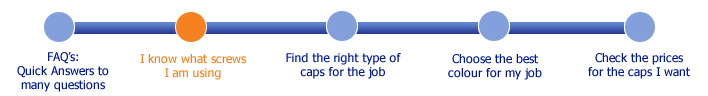

What Screws am I using?

To choose the right type of caps, you MUST know about the screws you will be using

|

Visit your local hardware store or fastener supplier and you will soon discover there are many different types of screws available.

The type/size of cover cap you need very much depends on what type and size screw/fixing you will be using.

Screw head:

|

.jpg) |

There are many different styles of screw heads to suit many different needs. For our purposes , we can narrow the types down to 2:

Countersunk screws: Screws that can be sunk or bored so that the top of the screw is flush with the surface

| |

|

Countersunk Head (aka Flat Countersunk or Flat Head) |

Designed so the screw head sits flush with the surface being fixed. Depending on the material being used, a countersunk bore may need to be pre-drilled into the material for the screw head. |

| |

|

Raised Countersunk

(aka Oval Head) |

No longer widely used, this countersunk screw incorporates a raised head - largely as a decorative feature for use with metal 'cup' washers. |

| |

|

Bugle Head |

Used primarily for plasterboard and drywall. A variation of the countersunk head, with a curved surface under the head (like a bugle), which reduces damage to the board while it is being fixed. |

'Flat-bottomed’ screws: Screws that sit proud of the surface (this includes pan-heads, mushroom heads, cheese heads, hex (bolt) heads.

We refer to these as ‘Flat-bottomed’ screws (as the bottom of the screw head is flat)

| |

|

Pan Head

(similar to Round, Mushroom & Domed Head) |

Typically used with self-tapping thread screws. The large surface area provides good clamping force on the material surface. The screw head sits above the material surface |

| |

|

Flat Head

(similar to Truss & Binder) |

These are wide yet low profile heads which provide a large surface area on top of the fixed material, without protruding too far. |

| |

|

Flange Head

(aka Washer Head) |

The flange (sometimes referred to as a 'Washer' - even though it is integral to the head, acts to increase the clamping surface area as the screw is tightened. |

Size of screws:

Screw sizes are listed in either Imperial or Metric. A typical Imperial screw may be shown as 8G x 1½”. Sometimes the ‘G’ or the inches (“) designator may not be used. A typical Metric screw size may be shown as M4 x 35mm ( although sometimes the ‘M’ or ‘mm’ may be missing). For what it is worth,

For both Metric and Imperial, the second number refers to the LENGTH of the screw (1½” or 35mm). While this length is very important depending on how you are using the screw, it is irrelevant to using a cover cap.

The first number (8G or M4) refers to the thickness or gauge of the wire that is used in making the screw. For most screws, this is the finished thickness of the shank and thread. So, measuring the diameter (width) of the screw tells us the size of the screw. A measurement of 4mm gives a screw size of M4.

So, you choose a screw by selecting the type of thread you need, which more often than not will also dictate the head-type you use.

The thickness (gauge) and the length of the screw you use will be dependent on your unique application, including what the screw is being screwed into, thickness of materials, weight of what you are attaching, etc etc. You should discuss this with a staff member of your hardware store/screw merchant, who should be able to advise you.

Thread type:

The second important thing to know is what thread type you need. Whilst there are literally hundreds of different thread types, most screws are suitable for screwing into either 1) wood or 2) metal or plastic. If you are screwing into masonry (brickwork, cement etc) then you will need to use a plastic wall plug (sometimes known as Rawl* plugs). Although screws with a thread for metal/plastic can be used, generally you will get a better result using a screw with a wood thread.

Now, here’s the important bit. More than 95% of screws with a wood thread have a countersunk head. And, more than 90% of screws with metal/plastic threads have a pan-head or other flat-bottom head. So, if you are screwing something into a wooden beam behind a wall, you will most likely use a Countersunk head, wood thread screw. If you are screwing something into plastic or metal (such as a metal purlin), you will most likely use a pan-head screw with a self-tapping thread (ie you drill the hole, but the screw thread can cut its own path through the metal)

Drive Types:

Lastly, different screws/fixings will have different drive types. Each type of drive recess requires its own specialised tool and many types have different sizes of drive recess

[Pozi], [Phillips], [Torx(aka ‘star’)], [Allen Key (aka Hex)], [Square drive], [Slotted (aka Flat-Blade)], [Security]

Some drive types are very prone to slipping (using a flat-blade screwdriver in slotted-head screws are notoriously difficult – especially if screwing horizontally or upwards) whilst others may result in the driver jamming in the screw’s drive recess (drives such as Torx or Square were designed to avoid such problems).

The writer’s views are that you should ensure you have a suitable driver (tool or bit) to go with the screws you are using and that slotted drive screws should not be sold at all in the 21st century!

So, now that you can identify what screws/fixing you are using, you can now consider which type of covercap will best suit your needs